Acknowledgement

We are very grateful to Mrs. Smita Adhikari for her valuable

suggestions, inspiration and full support for making it possible to perform a

brief case study on microprocessor based instrumentation system according to

the syllabus of Instrumentation-II and present this report within a short

period of time.

We are also grateful to the Electrical Department, PaschimanchalCampus

for providing us the recommendation letter subjected for visit to the industry.

We would like to thank Er. Ghanshyam Poudel from Kulekhani II for managing his

valuable time to show around the plant and providing information as per our

requirements.

We solely take the responsibility of any possible mistakes that may

have occurred in preparing this report and we would like to welcome comments

and queries during the presentation of this report.

Abstract

This report is prepared as per the visit for Case

Study based on microprocessor based instrumentation system included in the

syllabus of Instrumentation-II. This report includes brief introduction of

Khulekhani 2 Hydropower plant, detailed study of the instrumentation system

available at present in the Plant, and its characteristics. This report also

presents suitable alternatives and advancement to the existing instrumentation

system.

Like all production industries, Hydropower plant uses

a large number of instrumentation devices such as sensors, Mechanical equipment

and other electronic devices. These devices are synchronized very precisely so

as to meet the required flow of process. A single disturbance or error in a

system affects all the systems and devices connected together as well as other

instruments connected through that transmission line. That is why necessary

beforehand mechanisms and backup process are maintained to get through these

errors and maintain the stability and functioning of the whole power system.

We

studied the detail process and observe the possible changes that can enhance

the functioning and efficiency of the system. We also observed the process followed

in the global world and the improvement going in the Hydropower plant

around the globe. This report enrolls all the possible features that can be

implemented to this current system as per its hands on resources and other

technical difficulties.

Table of contents

Topics page

no.

1.

Introduction 1

1.1

Powerhouse

background 1

1.2

Salient features

2

2.

Current

process control system 2

2.1

Block

diagram 2

2.2

Features 3

2.2.1 Governor cabinet 3

2.2.2 Relay and recording Panel 6

2.2.3 Resistance Temperature Detector

(RTD) 6

2.2.4 Control room 7

2.3

Limitation 10

3.

Recommended

process control system 10

3.1

Block

Diagram 11

3.2

Features 11

3.3

Advantages

over existing system

14

4.

Recommendations 15

5.

Conclusion 15

6.

References 16

1.

INTRODUCTION

There is great potential of hydroelectricity in Nepal. According

to statistical record Nepal has potential of 83,000 MW hydroelectricity power

production. However, at present Nepal has produced only about 600 MW of

hydropower, which is not sufficient to meet the demand of whole country. Thus,

Nepal is facing serious attack of nearly 12 hours daily load shedding. This

directly affects the industrial field and overall development of the country.

The hydropower projects in Nepal are directly dependent on the

amount of water flowing in the river stream, so during dry season the power

production decreases significantly which results increase in duration of load

shedding. Among different hydropower models established in Nepal, Kulekhani is

only the hydropower project with reservoir. This type of hydropower can be the

permanent solution of the deep rooted load shedding.

The purpose of this research is to study about the technology that

are used in this hydropower for generation of the electricity, for controlling

the hardware equipment and manipulating the generated output electricity and

think about the new technology and equipment as well as the new manipulating

methods so that we can increase the production rate or to increase the

efficiency of the power house.

1.1

POWERHOUSE BACKGROUND

Kulekhani -2 Hydropower station,

located at Nibuwatar, Makwanpur, is a cascade of Kulekhani -1. Its installed

capacity is 32 MW having two units each of 16 MW. This powerhouse was designed

as peaking power station but it has been supporting as emergency stand by

station also. The annual expected energy generation capacity as primary energy

is 104.6 GWH. This project was constructed under the financial assistance of

Overseas Economic Cooperation Fund (OECF) of Japan and Government of Nepal at a

cost of NRs.124 million.

The main purpose for the

construction of this power station was to take the peak load only but the

unavailability of the sufficient power with respect to demand, the power

station was forced to operate as and when required.

1.2 Salient Features

Type :Cascade

of Kulekhani -1

Rated net head : 103.17 meter

Design discharge : 16.65 m3/s

Headrace tunnel : 4294 meter

Penstock pipe : 843 m long, 2.1 – 1.5m diameter steel pipe

Installed capacity : 32 MW

Turbine type and numbers : Pelton, 2 sets

Rated speed : 750 rpm

Type of generator : Vertical shaft, Synchronous

Capacity : 18.8 MVA

Rated voltage : 6.6 KV

Power transformer : 6.6/132KV, 1 phase, 12.6 MVA, 3 Nos

Average annual generation : 104.6 GWh

Commissioning date : 1986

Construction cost : NRs 124 million

Financed by :OECF and OPEC Fund

Rated net head : 103.17 meter

Design discharge : 16.65 m3/s

Headrace tunnel : 4294 meter

Penstock pipe : 843 m long, 2.1 – 1.5m diameter steel pipe

Installed capacity : 32 MW

Turbine type and numbers : Pelton, 2 sets

Rated speed : 750 rpm

Type of generator : Vertical shaft, Synchronous

Capacity : 18.8 MVA

Rated voltage : 6.6 KV

Power transformer : 6.6/132KV, 1 phase, 12.6 MVA, 3 Nos

Average annual generation : 104.6 GWh

Commissioning date : 1986

Construction cost : NRs 124 million

Financed by :OECF and OPEC Fund

1.

Current

Process Control System

The

water from reservoir is carried through penstock to the turbine which is

controlled by hydraulic control (valves). There are two different turbines each

of 16 MW capacities. The generated power at 6.6 KV is stepped up through step

up transformer and is transmitted to Control Room. Control Room monitors and

controls the power generation, power distribution and control of turbine

through governor cabinet.

2.1 Block Diagram

2.2 FEATURES

2.2.1 GOVERNOR CABINET

A

governor is a combination of devices that monitor speed deviations in a

hydraulic turbine and converts that speed variation into a change of wicket

gate servomotor position which changes the wicket gate opening. This assembly

of devices would be known as a “governing system”. In a hydro plant this

system is simply called the “governor” or “governor equipment”. This wicket

gate opening which is responsible for the flow of water to the turbine thus

controls:

·

Flow of water through the Penstock

·

Alignment of the generator’s shaft unit

(vertical in the case of Kulekhani 2)

·

Power Production

GOVERNOR COMPONENTS

The main parts of the governor are

·

A speed sensing device,

usually a ball head

·

An oil pressure system,

hydraulic valves to control oil flow, and

·

One or more hydraulic

servomotors to move the wicket gates

·

Auxiliary Control

Speed Sensor: The ball head is the

component that responds to speed changes of the unit- the turbine. There are

various designs of ball heads, but generally, they consist of two flyweights

attached to arms that pivot near the axis of rotation. The arms are attached to

a collar on a shaft. As the ball head rotational speed increases, the flyballs

move out because of centrifugal force pushing a rod down. The rod, usually

termed the speeder rod, acts on the pilot valve to route oil to the main valve

and the servomotors. A decrease in speed will cause the valve to move upward, allowing

the servomotor to drain and move in the opening direction. As the servomotor

moves open, the valve is moved down by the speed droop lever, centering it over

the port and stopping the servomotor. The unit is now operating at a slightly

slower speed, but the servomotor will not overshoot because for a given speed

the servomotor must move to a specific position.

Oil

Pressure System: The oil pressure system consists of

oil pump/s, oil accumulator tank/s, oil sump, and the necessary valves, piping,

and filtering required.

Flow Distributing Valves: The

hydraulic system consists of an oil sump, one or two oil pumps, an air over oil

accumulator tank, and piping to the servomotors. Typically, there are two pumps

with lead and lag controls so that there is always a backup pump. Some systems

will share two pumps between two units so that in an emergency one pump could

be used for both units. The accumulator tank is usually sized so that in the

event the pumps fail, the gates can still be closed.

The size of the valve required to control the large amount of oil

flowing to the servomotors is too large to be controlled by the ball head.

Therefore, a hydraulic amplifier system is used. Oil is routed to a servo on

the larger valve by a small pilot valve. The pilot valve is very small so that

it is sensitive to the small forces that result from small changes in speed.

The larger valve may be called the main valve, regulating valve, control valve,

relay valve, or distributing valve. The pilot valve usually is designed with a

moveable bushing. The plunger of the pilot valve is connected, through a

floating lever, to the ball head, and the bushing is connected to main valve.

Whenever the pilot valve moves off center, oil is routed to the main valve

servo, causing the main valve to move. The pilot valve bushing is moved off

center by the main valve movement, blocking the port of the pilot valve,

stopping further main valve movement. The restoring lever between the main

valve and the pilot valve bushing is usually adjustable so that the ratio of

pilot valve movement to main valve movement is adjustable.

Auxiliary Control: Most

governor cabinets also have auxiliary controls that control the auxiliary

valves to control the gate position. Because of the relatively small ports of

the auxiliary valve, the gates are moved slowly and can be positioned

precisely. The auxiliary valve has no connection to the ball head, and

therefore, no speed control. Some of these auxiliary controls also react on the

alignment of the generator, that are based on the readings of the generator

guide bearings (upper and lower) and generator thrust bearings (that carry the

rotating weight of the rotor axis in the generator).

APPLICATION

It

is an important thing to understand that the government cabinet, as shown in

the figure, shows meters of various sensors such as speed meter, wattmeter,

etc. in analog calibration. These values will be seen by the person at site and

certain operations such as opening of valves, nozzle flows will be controlled.

2.2.2 RELAY AND RECORDING PANEL

This

unit is the statistical unit of the power house which takes electrical input

and gives mechanical change in flag as output. A protective

relay is an electromechanical

apparatus, often with more than one coil, designed to calculate operating

conditions on an electrical circuit and trip circuit breakers when a fault is

detected. Protection relays use arrays of induction disks, shaded-pole magnets,

operating and restraint coils, solenoid-type operators, telephone-relay

contacts, and phase-shifting networks. Protection relays respond to such

conditions as over-current, over-voltage, reverse power flow, over- and under-

frequency. Distance relays trip for faults up to a certain distance away from a

substation but not beyond that point. An important transmission line or

generator unit will have cubicles dedicated to protection, with many individual

electromechanical devices.

Relay panel includes relays such as overvoltage relay, over current relay, over

speed relay, percentage differential relay, time limiting relay, etc. These are

emf coils current signal trigger coils and signal coils that have directly

linked with recording panel. Recording panel includes over voltage for

generator circuit, over current for generator circuit, emergency stop, over

speed, etc. Flags trough which the operator manages the performances of power

house. The timely records of every hour are recorded through this panel. It

avoids malfunctioning and the performance of the power house elements.

2.2.3

RESISTANCE TEMPERATURE DETECTOR (RTD)

An

RTD is a device which contains an electrical resistance source which changes

resistance value depending on its temperature. This change of resistance with

temperature can be measured and used to determine the temperature of a process

or of a material. This principle based temperature measuring system was found

to measure the temperature of power house elements. As the temperature of power

house elements as stator, transformer, etc. changes the corresponding

resistance changes and can be seen on display.

2.2.4 CONTROL ROOM

Frequency control

VOLTAGE

CONTROL

• The exciter supplies the

field winding with direct current and thus comprises the “power part” of the

excitation system.

• The controller treats and

amplifies the input signals to a level and form that is suited for the control

of the exciter. Input signals are pure control signals as well as functions for

stabilizing the exciter system.

• The voltage measurement and

load compensation unit measures the terminal voltage of the generator and

rectifies and filters it. Further, load compensation can be implemented if the

voltage in a point apart from the generator terminals, such as in a fictional

point inside the generator’s transformer, should be kept constant.

• The power system stabilizer,

PSS, gives a signal that increases the damping to the controller. Usual

input signals for the PSS are deviations in rotor speed, accelerating power, or

voltage frequency.

• The limiter and protection can

contain a large number of functions that ensure that different physical and

thermal limits, which generator and exciter have, are not exceeded. Usual

functions are current limiters, over–excitation protection, and

under–excitation protection. Many of these ensure that the synchronous machine

does not produce or absorb reactive power outside of the limits it is designed

for.

2.3

LIMITATIONS

This hydropower project

was established in 1982, and there has not been improvements in technology

since then, so the limitations are basically due to the not implementing the

modern technology. The limitations that we found during our visit are listed

below:

Ø The

instrumentation system implemented in the powerhouse was open loop system i.e.

observation are made in control room and the manual commands are made

accordingly. The nozzle valve controls are controlled according to the load

power demand manually. The recording of powerhouse performance is noted

manually. Error handling and status signals are addressed by human operator.

This made the operation of power house dependent on manual work; we found this

as the main limitation of the power house.

Ø Large

use of mechanical switch instead of electronic switch.

Ø In

hydropower it uses all mechanical relays and flags and these are not replaced

by microprocessor based digital relays which have great precision and

maintenance capacity.

Ø The

commands form control room to power house was connected manually (through

phone), that should be connected electrically.

Ø The

machines used in the powerhouse are too old to use and are not updated

according to time.

3.

RECOMMENDED PROCESS CONTROL SYSTEM

3.1

BLOCK DIAGRAM

3.2 FEATURES

Programmable Logic Controller Concepts

Programmable

logic controller is basically a digital electronic apparatus; it has a

programmable memory for strong instructions to implement specific tasks for

control.

Advanced

PLCs are microprocessor based and can perform complex mathematical calculation

and function as well as logic, sequencing, timing and counting.

The

major components of a PLC are:

1. Processor

2. Input

Modules

3. Output

Modules

4. Programming

and Other Facilities

Component

Description:

Programmable

logic controllers typically contain a variable number of input/output (I/O)

ports and usually employ reduced instruction set computing (RISC), which

consists of simplified instructions that are intended to allow for faster

execution.

Input

Interface provides connection to the machine or process being controlled. The

principal function of the interface is to receive and convert field signals

into a form that can be used by the CPU.

CPU

provides the main intelligence in the PLC as is evident in every other system. The

output Interface takes signals from the processor and translates them into

forms that are appropriate to produce control actions by external devices.

General Concept:

A

hydropower operation will typically involve many operations and steps. Some of

these steps would occur in series and some would occur in parallel. Some events

may involve discrete setting of states in the plant like valves open or closed,

accessories on or off, and so on. With

help of PLC, use of hardwired relays is minimized. A large PLC has enough

number of relays to do all the operations. The advantages of these relays are

that these are

Digital,

so minimum damage to the system, cost reduction and less maintenance is

involved in their use. If there is any need to change the control system, only

the program is to be changed and it can be done easily without any cost

involvement.

In

continuous processes we may need to convert the analog signal to the acceptable

value to the PLC and then with A/D converter it is converted to digital input

to processor. A control algorithm is to be developed to get a control signal to

control the variable. There is always a set value to which the variable is

taken. By calculating the error, algorithm can be applied to get a control

signal. This control signal is then converted to analog signal and then

amplified to control the variable.

·

Automatic Start Sequence

·

Automatic Shutdown (Normal, Emergency).

·

Digital Governing using PLC

·

Speed Governing

·

Position Control

·

Protection System with PLC

·

Alarm and Annunciation using PLC

User Interfacing:

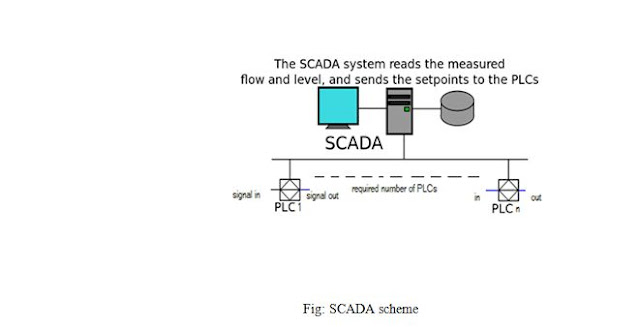

SCADA (Supervisory Control and Data

acquisition)/HMI concepts

Even though PLCs are responsible for automated control one needs

to keep an eye on all the processes taking place in the station and the house.

SCADA is a control system that is used for centralized monitoring and recording

of pumps, tank levels switches, etc. That is SCADA is there for supervision of

activities. Its components are:

·

A Human Machine Interface (HMI):

Monitor most commonly.

·

A computer system: used to

gather information and send control commands

·

RTU (Remote Terminal Units)/

PLC: connected to the physical equipments and convert actions to digital

signals. All major PLC manufacturers have offered integrated

HMI/SCADA system thus PLC are chosen above special purpose RTUs.

Visualization of plant status and condition, logging of events and

metering, and annunciation of alarm conditions are generally managed by the

station through HMI (Human Machine Interface). It serves as the local

operator’s portal into the process. The feedback control

loop passes through the RTU or PLC, while the SCADA system monitors the overall

performance of the loop.

In

this way, the operator can sit in his room and watch what goes on through the

plant and control the actions from there if required. But this isn’t the only

advantage the automation provides.

Some

of the pros are:

·

Increased system

availability and visibility

·

Decreased downtime

requirements to recover from a failure

·

Decreased cost in materials

and man hours for installation

·

Ease of control

1.3 ADVANTAGES

OVER EXISTING SYSTEM

Our purposed system consists of digital electronic devices which

are microprocessor based (PLC, SCADA).Thus this system is highly advantageous

over existing system.

Ø

One of the most important

improvements of our purposed system is that it provides automation.

Ø

It possesses centralized

monitoring and recording of pumps, tank levels switches +etc.

Ø

It is capable of performing complex

mathematical calculation and function as well as logic, sequencing, timing and

counting.

Ø

With help of PLC, use of hardwired

relays is minimized.

Ø Increased system availability and visibility.

Ø Decreased downtime requirements to recover from a failure.

Ø Decreased cost in materials and man hours for installation.

Ø Ease of control.

4.

RECOMMENDATIONS

v Implementation of electronic PLC over the mechanical governor

cabinet components.

v HMI over analogue meters i.e. a computerized user interface and

monitoring system over the analogue meters in the control room.

v Proper installation of a system as per the outlines mentioned in

our recommended system that uses PLC for controlled output and HMIs for

supervision.

5.

CONCLUSION

Thus, the visit to Kulekhani 2, provided us with the information

on power generation and system control. Though system is robust and reliable

the presence of local operator within the powerhouse is a necessity. This

manual supervision throughout the powerhouse requires numbers. This can be

improvised with the use of an automatic control system where supervision will

be done from the control room and the device itself will make necessary changes

to any unusual processing. Further these changes can be monitored and any

interruption can be performed from the control room. Lastly we gained lots of

information on hydro power generation and controlled instrumentation

implementation.

6.

REFERENCES

Ø

ASME,

The Guide to Hydropower Mechanical Design,1996

Ø

Nepal

Electricity Authority

Really informative report—appreciate how clearly it breaks down both the current instrumentation setup and potential upgrades for improved system reliability and efficiency. It’s fascinating to see how precision and backup systems play such a critical role in hydropower. On a related note, for those interested in exploring natural energy landscapes firsthand, Darjeeling offers a great blend of scenic beauty and hydropower relevance: https://northbengaltourism.com/darjeeling-tour-packages/

ReplyDelete